New well made factory instruments both German and Chinese are available for rental.

New well made factory instruments both German and Chinese are available for rental.

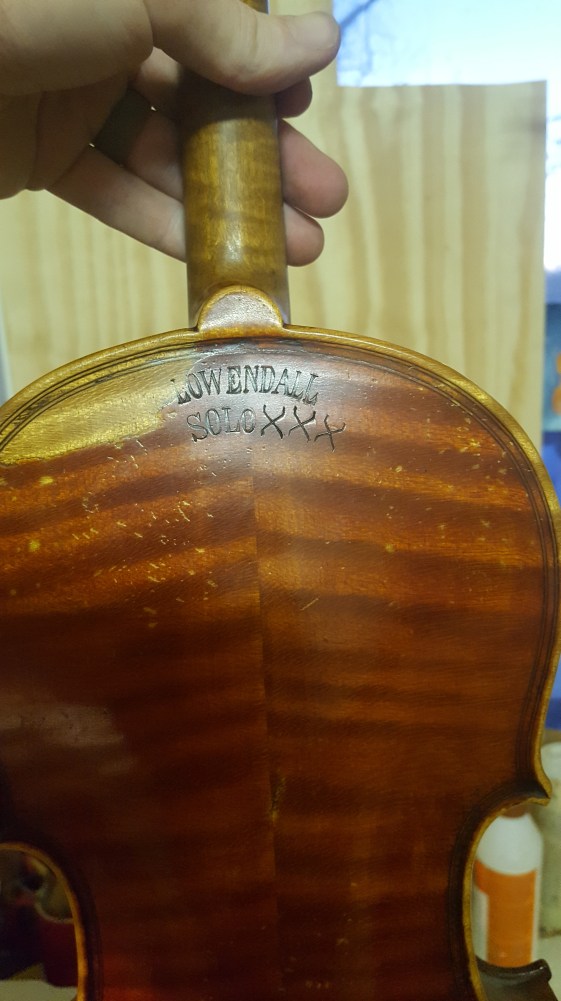

Violin LabelledGaspar de Salo en Brescia 1586

We’ve moved!

(Our new address is 37 N Railway Street, Okotoks AB)

The last few weeks we’ve been busy setting up shop just down the street in the shop of our late friend, Don Barnes. Tyler has been running Don’s instrument wood business, Grandpa’s Workshop, for several months since Don took ill early in the year.

Here are a few pictures from around the new shop…

View from across the street

All set up for communication!

Getting down to work.

Repairing the original sign.

Some storage solutions…

Just some of the instrument wood for sale through Grandpa’s Workshop.

(Check it out at http://buytonewood.com/ )